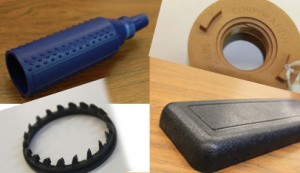

Insert molding

Threaded fasteners, close tolerance inserts for flash free results. Our ergonomic hand tools or robust threaded inserts for structural applications are highly desired.

Craftsmanship Due Care

Grains, logos, threaded cores, flash free parting lines, Class A parts

Thin Wall, High Tech Parts

Experts in parts qualification and tooling for our High Tech customers who need computer chip burn-in sockets and electrical connectors. Our mold bases are reconfigurable to all for maximum part types with minimal tool costs. We run to order just what you need minimizing your parts inventories.

We dimensionally certify every order and ship around the world.

Custom Plumbing Fittings

We mold for some of America’s well know Plumbing supply houses. Custom threaded fittings, soft gaskets and unique applications. Let us assist in creating a niche market for you as well!

Material Handling/Agri-Chemical Closures

There is little doubt that you have seen some of our molded parts: Pour control spouts, tamper proof, gasket, automatic sealing valves, decorative packaging. From consumer packing to industrial closures our experience is desirable.

Fire/Safety/Alert Products

Eye catching, ergonomically functional parts utilized by Emergency personnel. Visual Signals, Auditory Alerts, Fire Spray Nozzle grips, Masks

Protective Hard Cases for Fragile Instruments

Various sized cases, handles and inner liners protect your product during shipping and throughout its useful life.

Various sized cases, handles and inner liners protect your product during shipping and throughout its useful life.

Family Mold Method

Multiple mold bases that accept 2 7/8″ round dies in a 4 and 10 cavity configuration. Our 2 7/8″ by 5 7/8″ dies will carry up to 12 cavity bushings or O-rings for customized parts. Our square block MUD bases with cavity capacities 08″ and 09″ die blocks. Specialty fasteners, plastic grommets, connector bodies, gears, plastic screws and washers up to 12 cavities are possible with low tooling investment.

General Processes

Injection molding, assembly operations, mold & machine maintenance, drilling/machining/die punching, 3rd party logistics

Assembling/Secondary Operations

Sonic weld/ spin weld, PSA tape application, machining/milling, Multi-piece assembly, Customer required PSA labels, O’ring or Tamper proof assembled

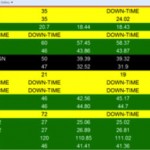

Production Systems

Real time monitoring with flat screens in production, inventory & logistic management

In-house Tool Room

Complete mold shop with several Tool Builder Journeyman’s licensed being experts in tight tolerance family mold.

In-house QA with critical dimensions checking machines

24 hour QA staff with dedicated gaging room and several mil-spec checking machines supporting our ISO9001 certification.